Description

Product Specification

| Power supply | Three phase, 380V/415V, 50/60Hz |

| Motor in HP (equivalent kW) | 40HP (30kW) |

| Speed range (variable speed electronically controlled) | 500-1000rpm |

| Impellers | 8 pieces of Teflon Agitator Discs |

| Machine Base | SS304/Powder Coated MS Base with forklift channels |

| Separation System | Centrifugal with customizable mesh screen |

| Seal | Double mechanical seal Tungsten Carbide |

Milling Chamber Specifications

| Grinding chamber volume (m3) | 40 |

| Wetted parts material | Food and medical grade stainless steel 316L/304 |

| Batch Size (litres) | 100-500 |

| Typical throughput rate (kg/h) | 100-700 |

| Grinding beads diameter (mm) | 0.5-2.0 |

| Recirculation Pump Rate (GPM) | 90 |

Optional

| Mobile frame support with castor wheels |

| Panel control with frequency inverter |

| Touch screen panel control |

| PLC for automation |

| Sanitary (GMP) design |

| Various hopper size for beads input |

| Explosion proof motor & remote control station |

| Inline High Shear Mixer for pre-milling |

| Jacketed vessel for product recirculation |

| Industrial chiller for cooling of chamber |

| Special seals, valves and fittings |

| Digital countdown timer |

WHY HORIZONTAL BEAD MILL?

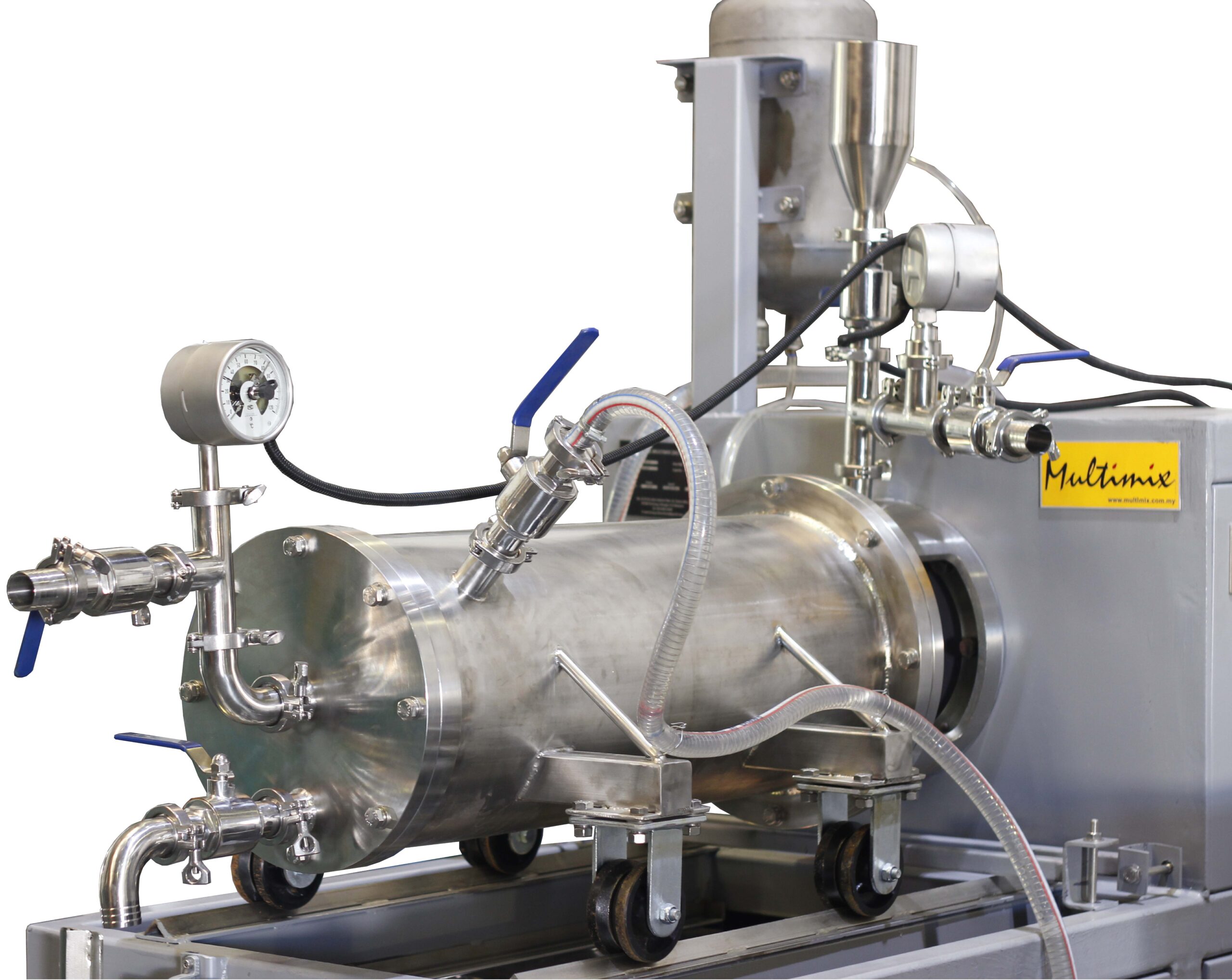

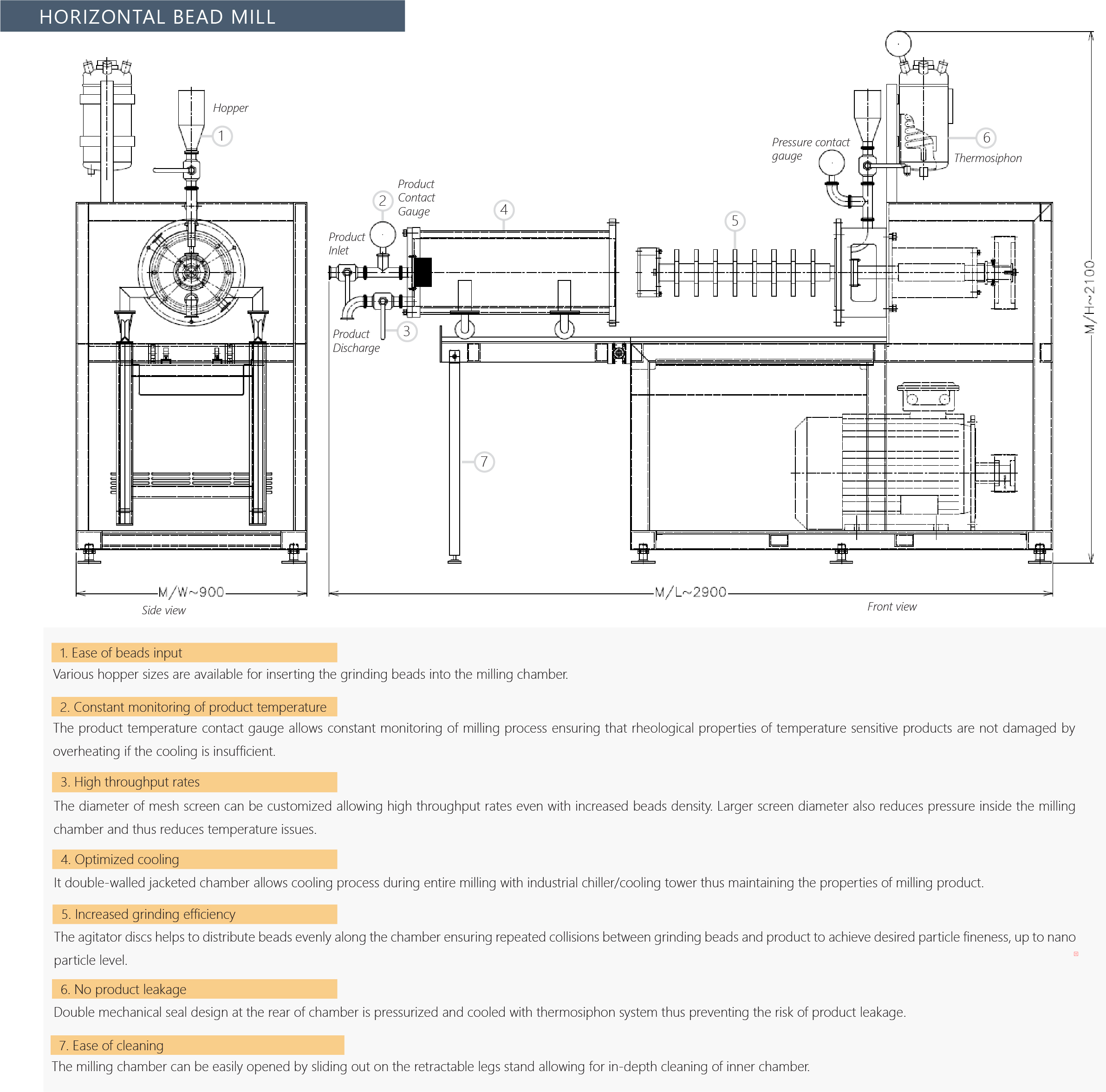

The horizontal bead mill is mainly used for wet milling or grinding of solid-liquid two phase system, whereby the aim is to achieve super fine particle size (up to micro/nano level) of the liquid phase..Mainly used in paint, ink and coatings industry.

HOW IT WORKS?

This is achieved through mechanical action of continuous pounding impact/collision from solid zirconium beads with the liquid phase, thanks to rotating grinding discs inside of the milling chamber. The milling chamber is usually a jacketed one and connected to a cooling tower/chiller to prevent product from overheating due to long hours of milling

Once the desired particle size is achieved and product is ready for discharge, there is a beads separation screen to remove the zirconium beads from the liquid phase.