Description

Product Portfolio

| Model | Power (HP) / RPM | Shaft Length (mm) | Capacity (H2O/liter) |

| BPM 103 | 3/200 | 750 | 100 |

| BPM 105 | 5/200 | 850 | 200 |

| BPM 110 | 10/200 | 1100 | 1000 |

| BPM 125 | 25/200 | 1300 | 2000 |

| BPM 130 | 30/200 | 1400 | 3000 |

| BPM 150 | 50/200 | 1600 | 5000 |

Product Specifications

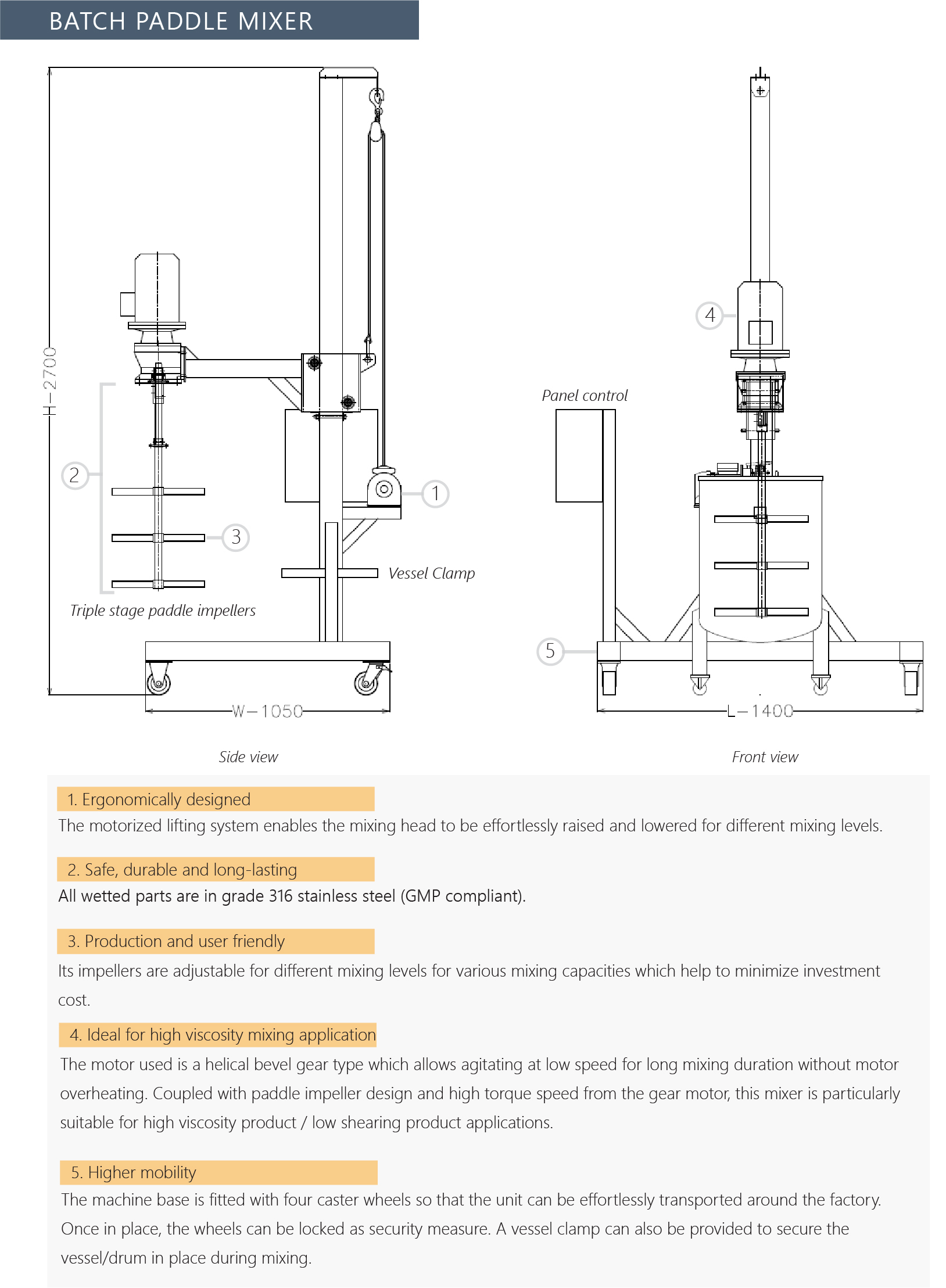

| Power Supply | Three phase, 380V/415V, 50/60Hz |

| Speed | Electronic variable speed inverter |

| Wetted Parts Material | Food and medical grade stainless steel SS 316L |

| Mixing Impeller | Single/Double/Triple staged Paddle Impeller |

| Width | 300-1000mm (as per tank diameter) |

| Coating | Teflon (optional) |

| Machine base | Mobile with castor wheels and safety locking mechanism |

Optional Features

| Explosion proof motor EEX D ll T4 |

| Remote control station for ex-proof motor |

| Stainless steel mobile jacketed tank |

| Customizable shaft length as per tank depth |

| Interchangeable impellers e.g. dissolver blade |

| Safety features |

| Panel control with frequency inverter |

| Mobile motorized electrical lifting system |

WHY BATCH PADDLE MIXER?

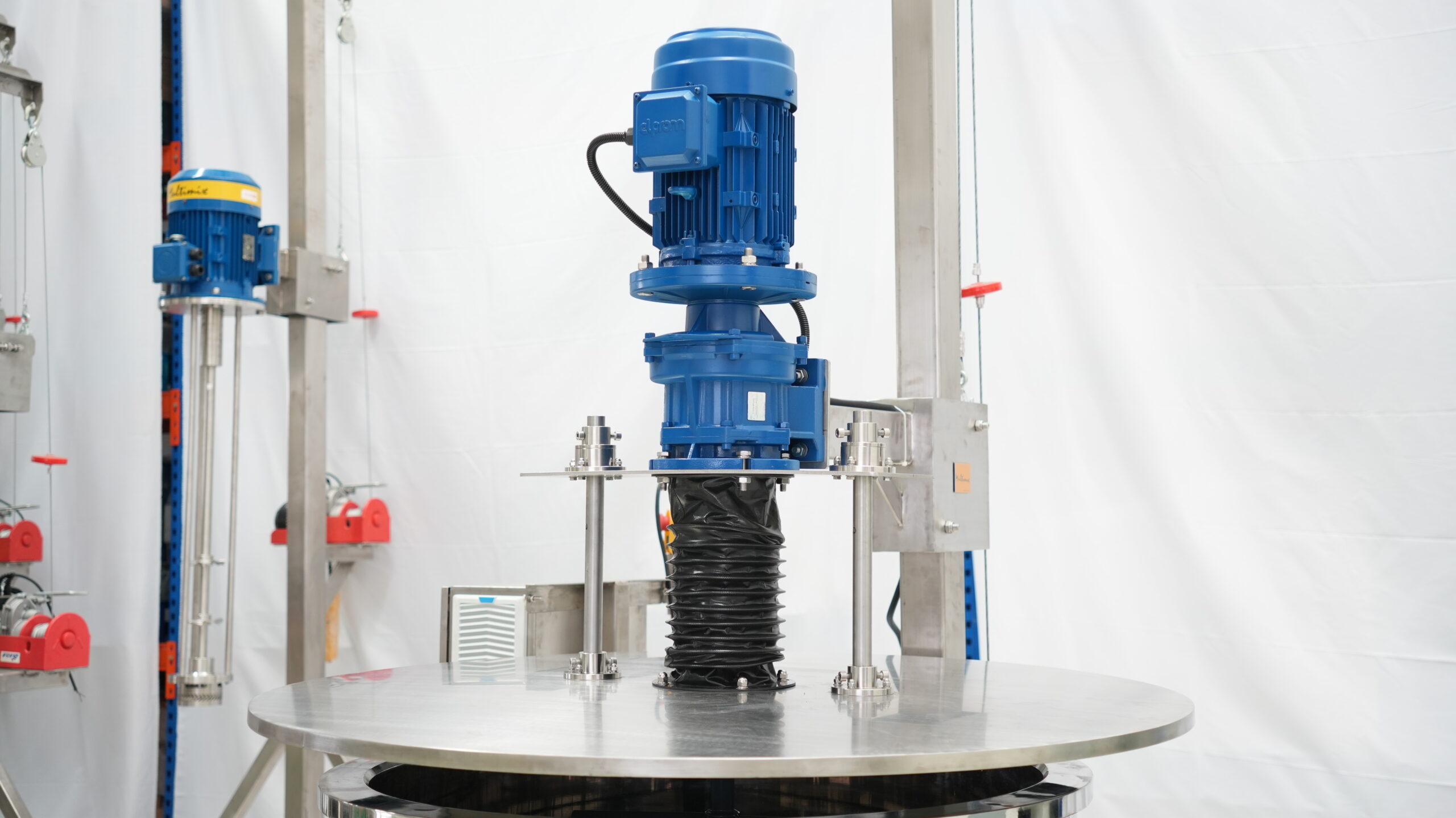

Multimix Batch Paddle Mixer Series is specially designed for mixing application at low speed for long hours, thanks to helical gear motor design. It is also widely used for medium to high viscosity mixing applications where shearing is not required or needs to minimize due to product nature which might change due to heat generated by shearing.

The direction of paddle impellers can be reversed depending on customer application.

HOW LOW SHEAR MIXER WORKS?

At the core of each Batch Mixer unit lies the paddle impeller which creates laminar flow of mixing without causing further shearing to the product.

The paddle impeller can be customized at single/double/triple stages depending on product applications.

BATCH PADDLE MIXING APPLICATIONS

- Cosmetics : Cream, emulsion, essence, gel, moisturiser

- Personal Hygiene and Care: lotions, shower gel, shampoo, conditioner,

- Disinfectants, hand sanitizer

- Xanthan Gum/Carbopol/Carbomer dispersion

- Formulated dairy products: cream cheese, flavoured milk,

- Food and beverage: soups, broths, sauces, dressings, ice cream toppings, mayo