Description

Product Specifications

| Motor | 5HP/10HP/25HP/30HP/50HP/100HP

AC Motor in Aluminum Housing |

| Power Supply | Three phase, 380V/415V, 50/60Hz |

| Mixing impeller | Rotor stator 2- 4 stages |

| Speed | Electronic variable speed inverter

0-1500/2500/3000 rpm |

| Material | SS 316L wetted parts |

| Mixing Capacity | up to 10,000L |

| Inlet/Outlet | SMS Union with hose fitting |

| Included | SMS opener |

| Optional |

|

WHY INLINE HIGH SHEAR MIXER ?

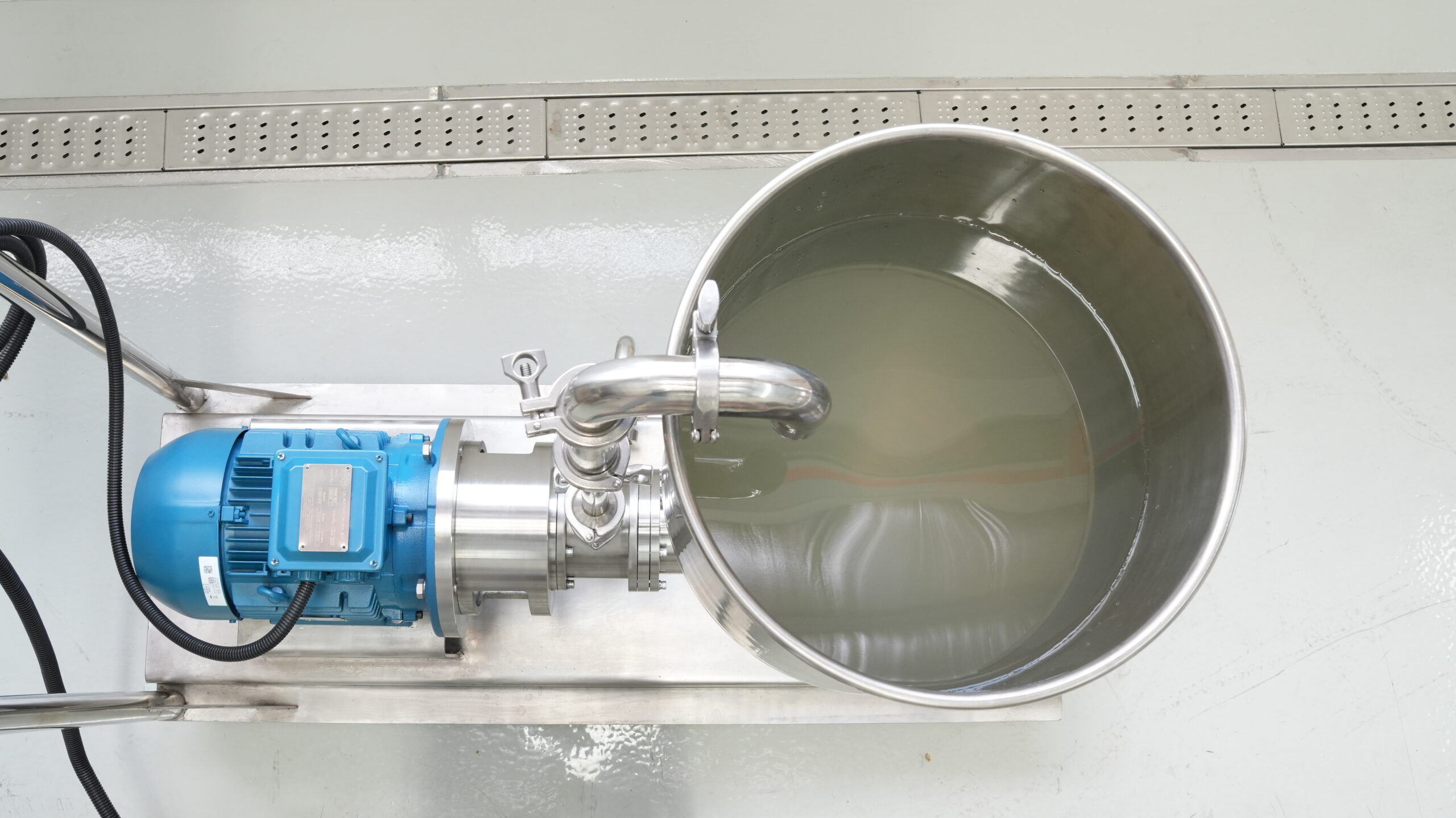

More often than not when it comes to industrial mixers, a bulky static mixing tank is often seen in production area. Not to mention the fact that space IS becoming a scarcity and precious resource for factories, an efficient, mobile and compact mixing powerhouse is what customers are truly looking for.

HOW INLINE HIGH SHEAR MIXER WORKS ?

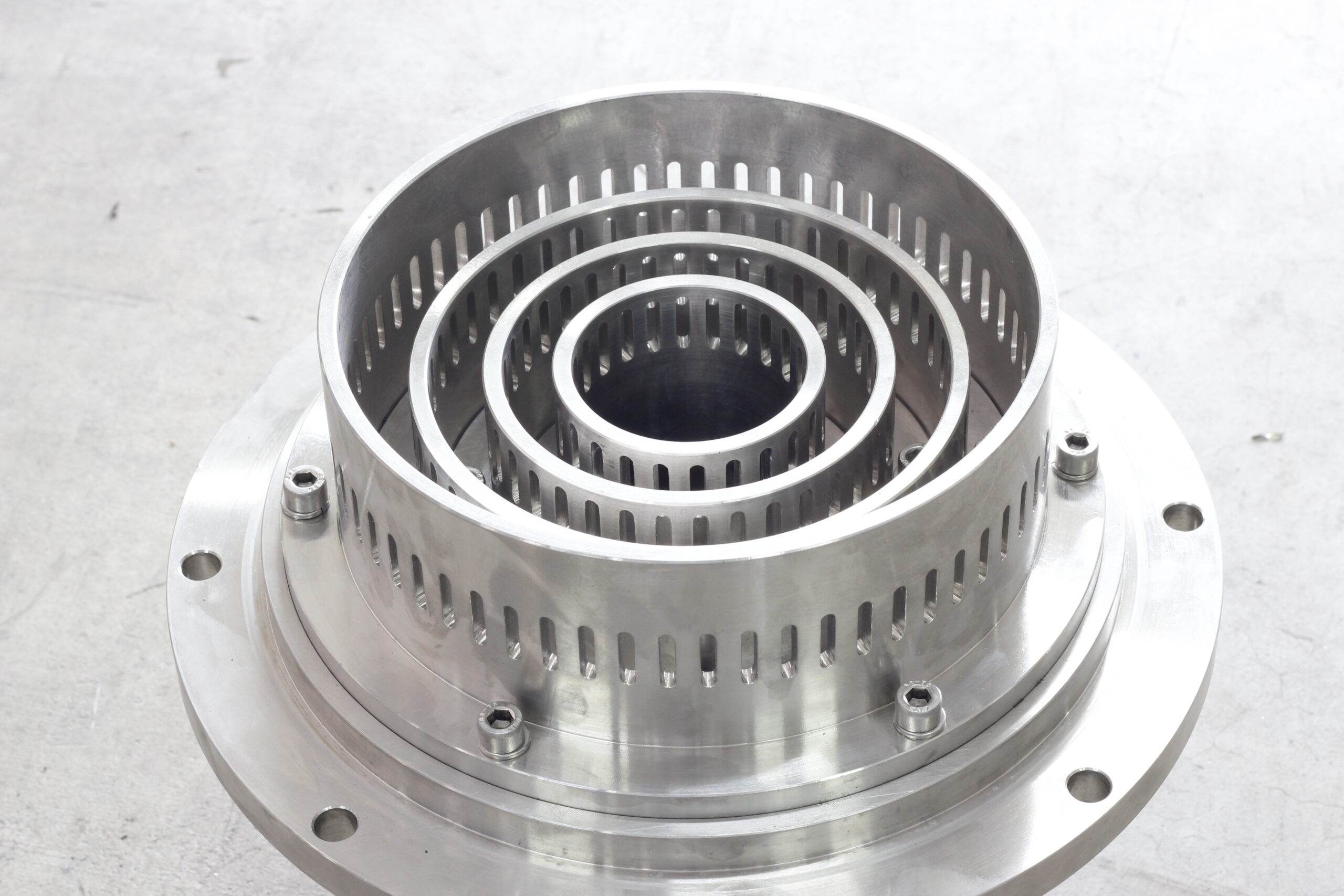

At the core of each Inline High Shear Mixer lies a precision engineered “slotted” stator, designed in double stage, triple stage and up to a maximum four stages. Coupled with the vortex generated by the rotor inside, such design allows maximum shearing of particles as they are sucked and pushed through the sharp edges of the slots.

Powder /oil can be effectively wetted and dispersed into the liquid via the hopper (25L/50L) and recirculated through the multi stages stators until required emulsion texture is formed.

INLINE HIGH SHEAR MIXER APPLICATIONS

- Gum dispersion such as Carbopol or Carbomel as thickener

- Sauces and ketchups

- Cough syrup mixture