The customer wants to upgrade their production facility as they are moving into a bigger factory and further improves on their compliance to GMP and food safety requirements.

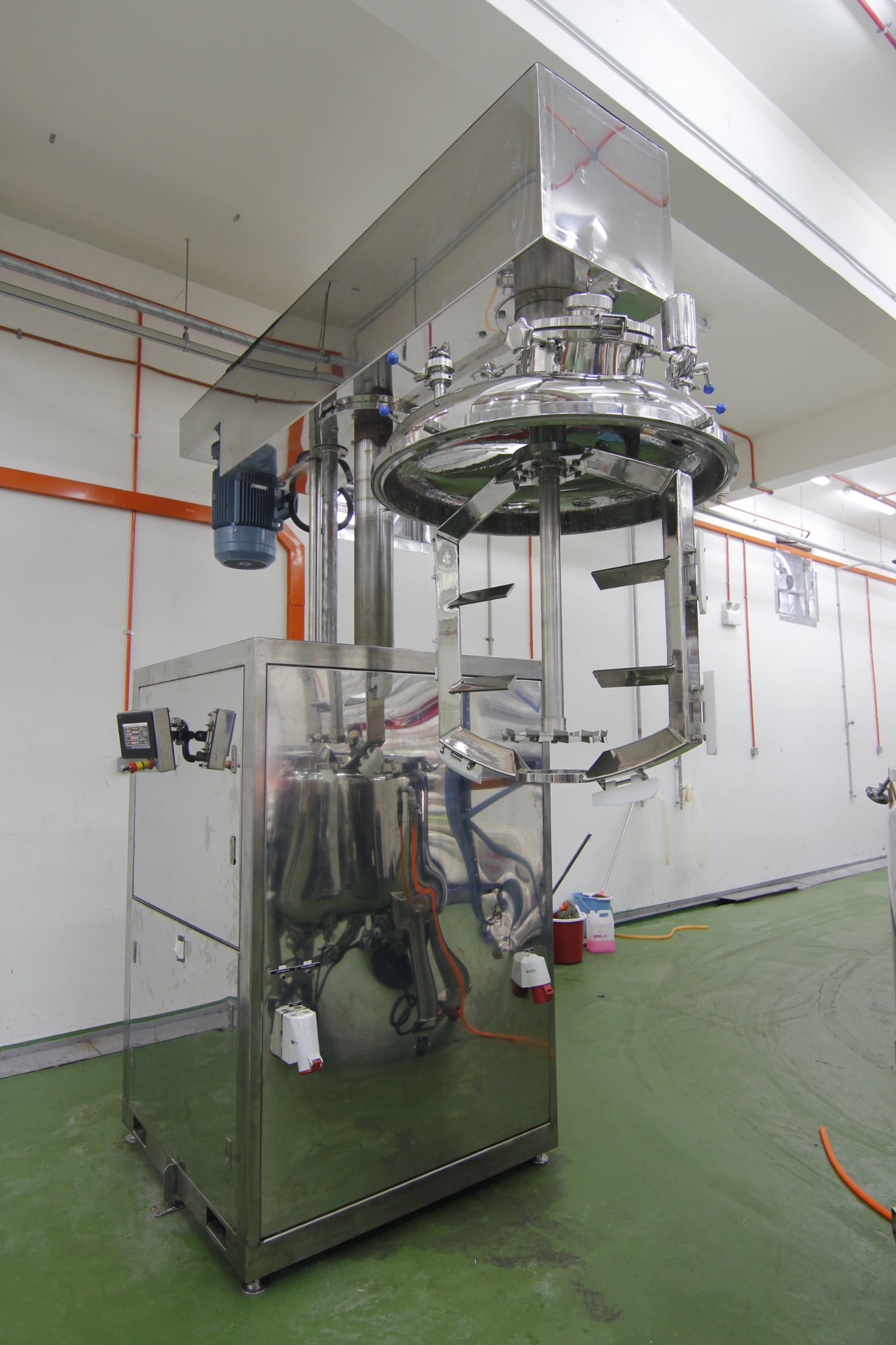

Most notably, they are moving away from traditional mixing method and asked for our advice for modern mixing technologies which helps them to improve and cut down on production times. For example, the vacuum mixer is equipped with touch screen PLC panel allowing programming and setting of various mixing times depending on their production schedule.

Also the inline high shear mixing system ensures top homogeneity in the end product and improves their end product quaility perception. The built-in heaters inside the jacketed vessel allows them to sterilize the vessel before start of mixing and consequently during the mixing thus effectively pasteuerizing the product without transferring in/out product to different vessels. This represents a huge cost savings in terms of production time.

- Flavouring Food & Beverage