The customer wants to produce mayonnaise with cold process and asked for our advice for modern mixing technologies which helps them to improve and cut down on production times. For example, the vacuum mixer is equipped with touch screen PLC panel allowing programming and setting of various mixing times depending on their production schedule.

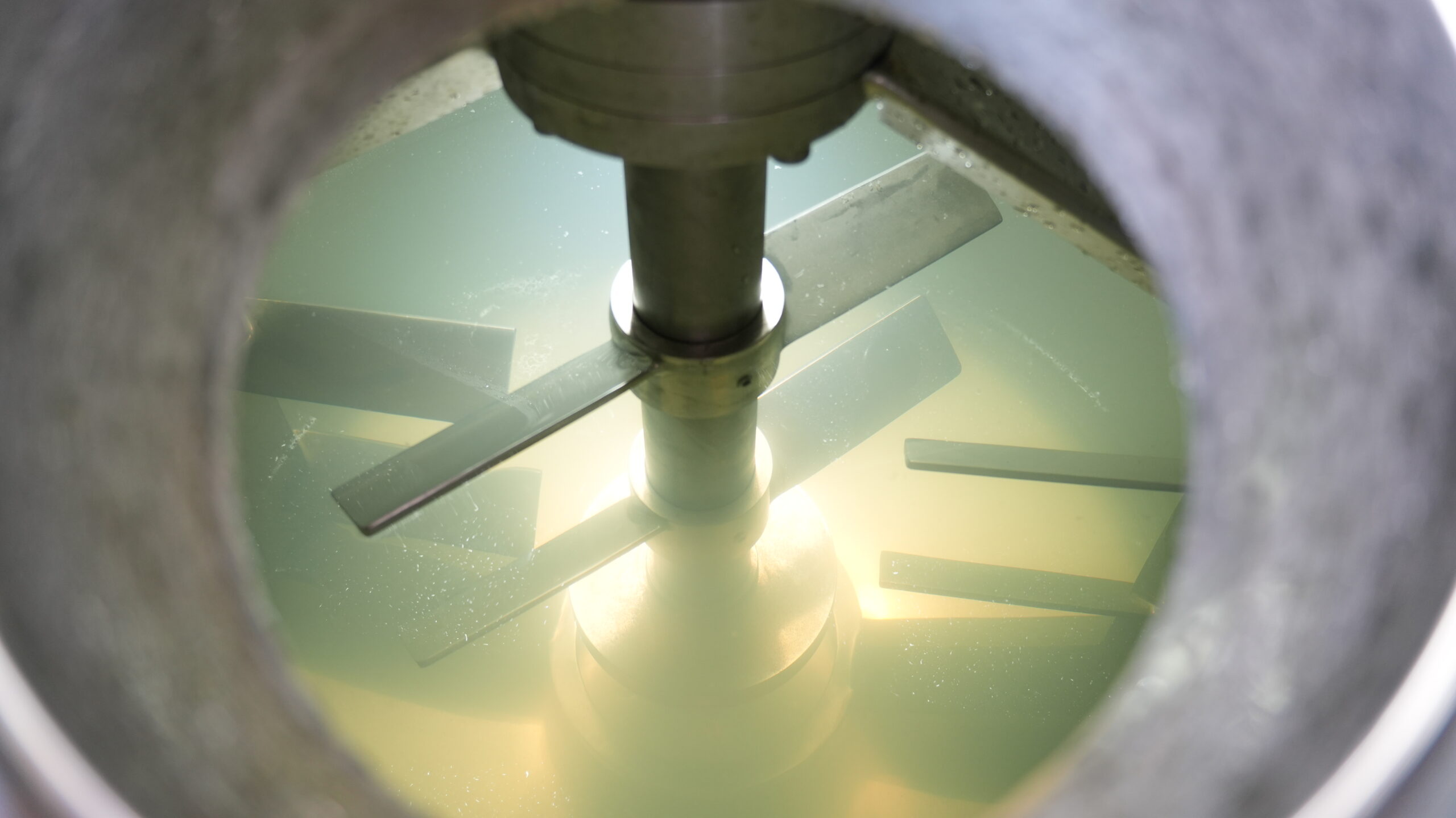

Also the premix tank with high speed disperser allows premix of powder into liquid before emulsifying stage in main tank. The jacketed vessel allows them to do cold/hot process via external industrial chiller/circulating bath.

The transfer from premix tank is done using vacuum technology and ensures no wastage is stuck between the pipes and messy transfer thus saving a lot of production time.

- Flavouring Food & Beverage