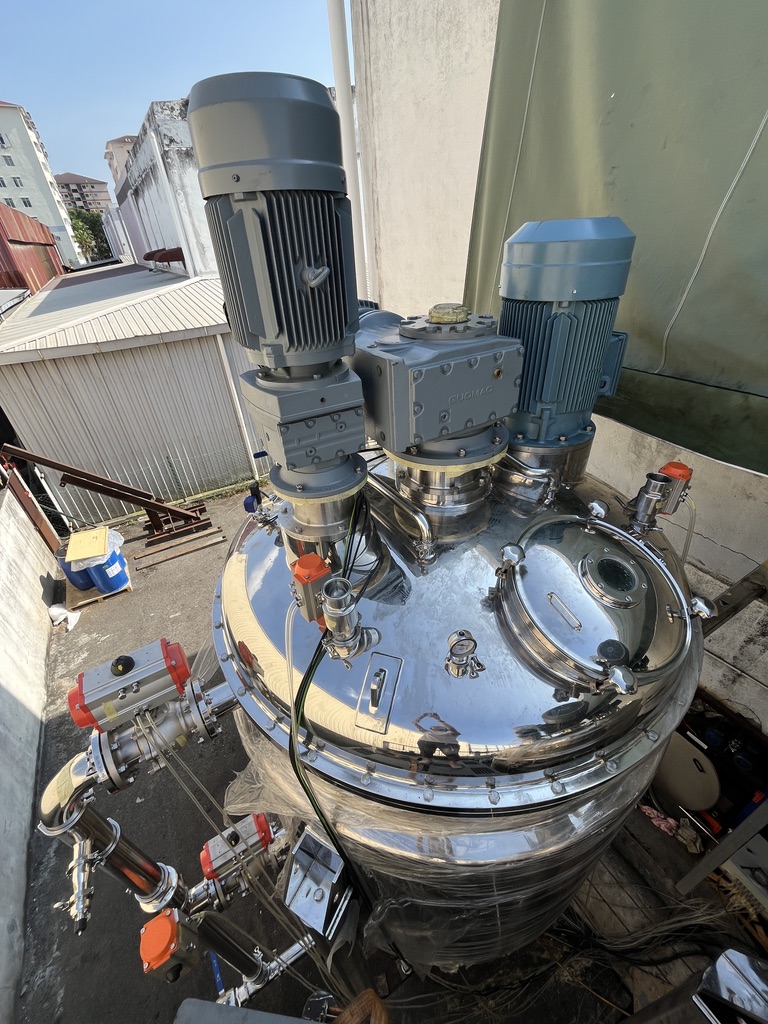

Simulation of toothpaste with Multimix Vacuum Anchor Disperser and Inline High Shear Mixer for a famous multinational Japanese toothpaste manufacturer during FAT.

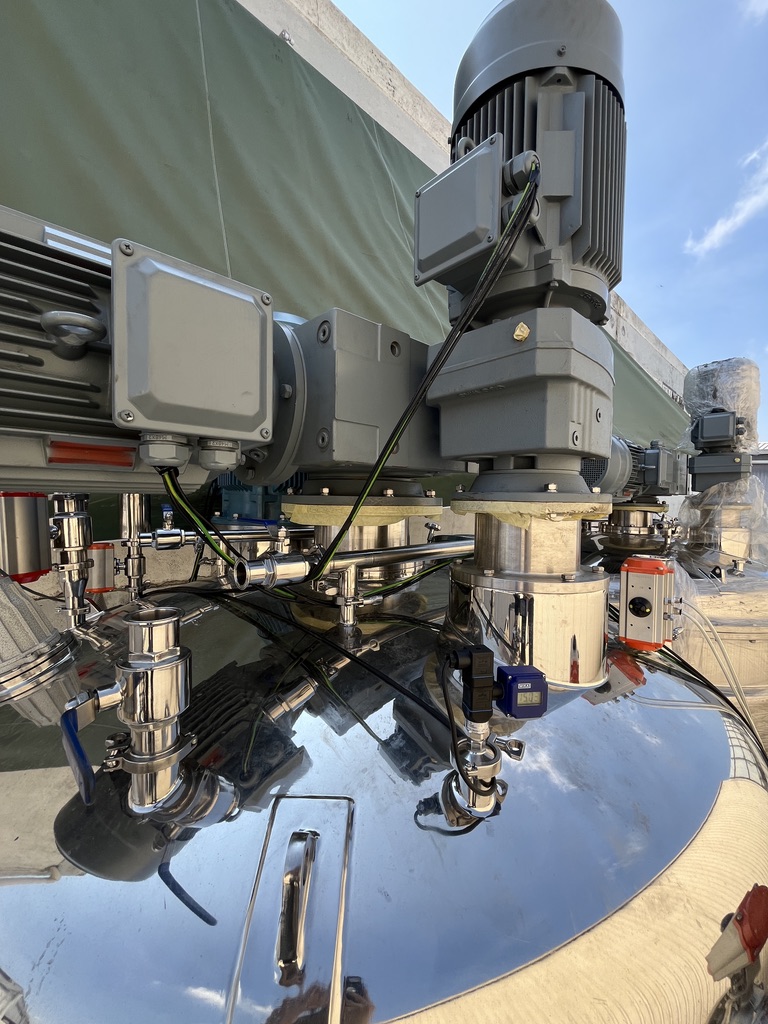

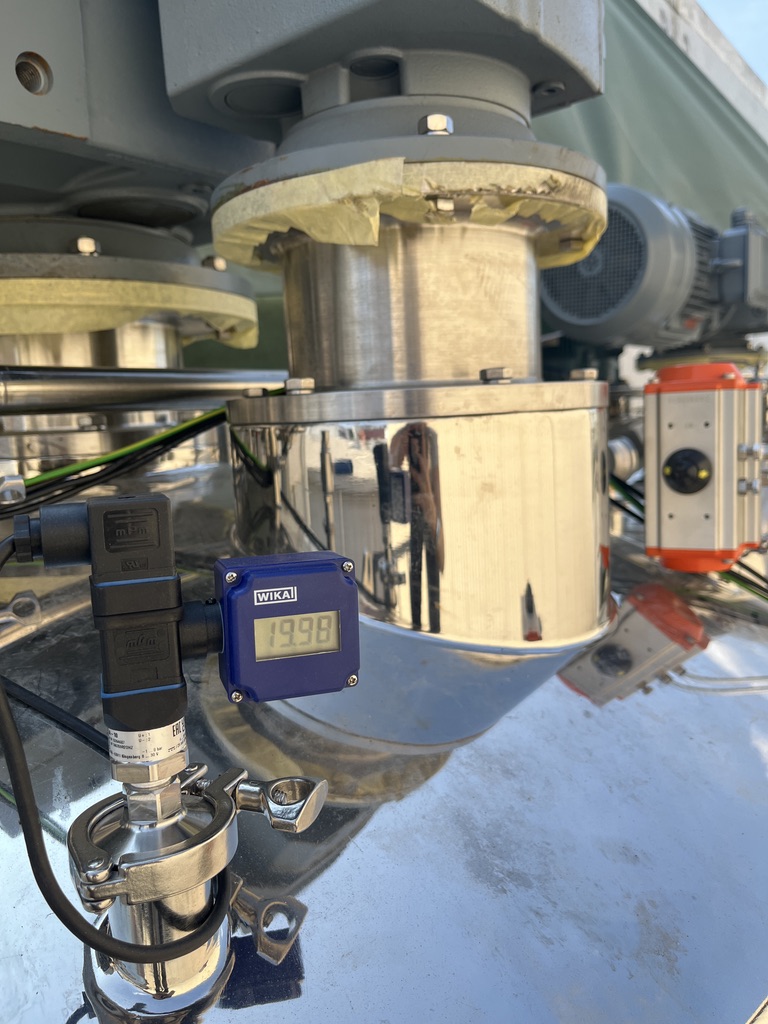

There are two-stages of disperser blades with special design coupled with anchor and paddle impeller to promote homogenous mixing while gum dispersion is mainly done by the inline high shear mixer and recirculated back to the main mixing tank of 4000L for further mixing with anchor and paddle impellers when the solution is becoming viscous.

All gum powders are transferred via vacuum suction for ease of material input ensuring hygiene at all times at production floor.

The whole mixer setup is controlled via multiple recipes input done in PLC programming.Not to mention that all valves are controlled pneumatically.

- Toiletries, Beauty & Cosmetics