No other mixer

like Multimix

CKL Multimix was established in 1996 and today Multimix is a leading industrial mixer manufacturer and supplier in Malaysia. We are also market leader in the vacuum mixing technology and machinery, specialized in incorporating vacuum technology with various mixing principles namely: Mixing, Dispersing, Emulsifying & Milling.

From Laboratory

Our mixers portfolio are wide-ranging from lab-scale mixers such as Laboratory Homogenizer, Lab Stirrer and Laboratory Vacuum Mixer to

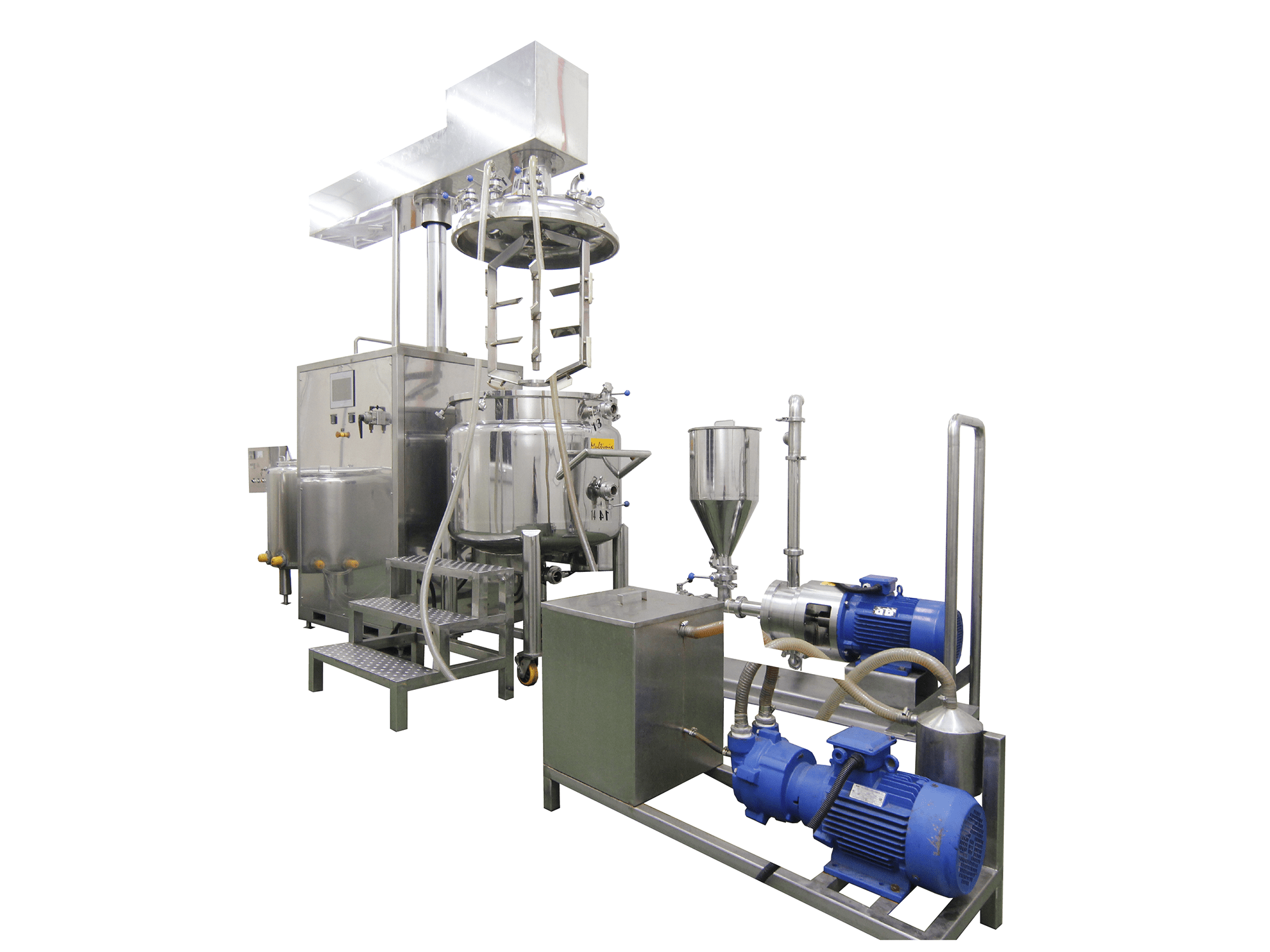

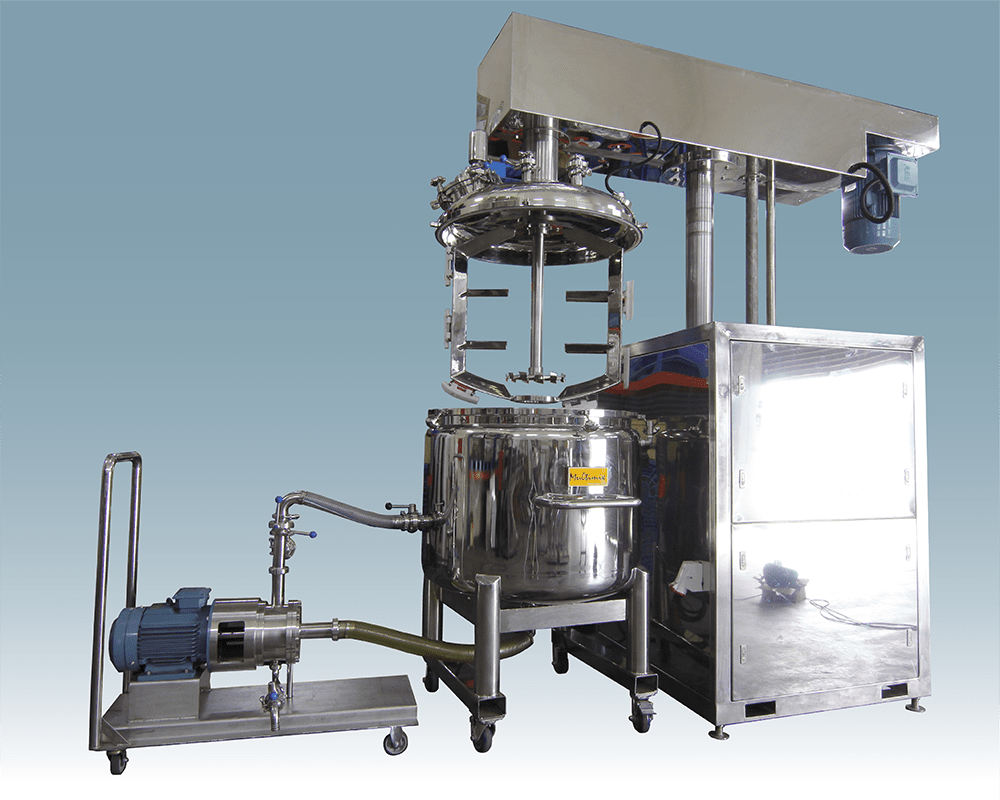

To Production

production-scale mixers such as Vacuum Mixing Tank, High Shear Mixer, In-Line Homogenizer, Batch Mixer, Powder Mixer, Powder Liquid Mixer, Fluid Mixer (IBC Mixer) and High Speed Disperser.

From Laboratory

Our mixers portfolio are wide-ranging from such lab-scale mixers such as Laboratory Homogenizer, Lab Stirrer and Laboratory vacuum mixer to

To Production

production-scale mixers such as Vacuum Mixing Tank, High Shear Mixer, In-Line Homogenizer, Batch Mixer, Powder Mixer, Powder Liquid Mixer, Fluid Mixer (IBC Mixer) and High Speed Disperser.

The main strength of Multimix is to provide a simple, practical, cost efficiency and versatile knowledge in the various mixing and processing applications. Multimix has developed revolutionary processing know-hows in the production of emulsions & dispersions. Today Multimix is able to produce fine emulsion at Nano particle size and fine dispersion without “fish eye” which are two important components in any mixing process.

Multimix has developed patented “Vee” type of rotor/stator. The stator has a special Vee¬shaped slots cut in the circular rim which provide longest cutting or shearing edge to the mixing fluid in operation. The rotor also is “Vee” shaped providing extra high shearing force to the mixing fluid in operation. Therefore, Multimix unique design of rotor/stator provides both higher shear force and higher flow rate. These criteria are important when particle reduction and higher flower rate are required.

Multimix today has developed and provided a “Total Solution” to the processing applications.

Multimix is able to reduce production time and enhance productivity, improving product’s quality by introducing new ways of processing methods.

Conventionally, in the production of toothpaste industry which requires 4 to 5 hours of production time, with Multimix, customer is able to reduce production time to within maximum 1 to 1.5 hours only, which tremendously increases production efficiency and at the same time improves the product’s quality and finishing.

Multimix has a strong market share in Malaysia in the production of latex compound which is widely used in the rubber glove and condom industry. Multimix has developed a simple and efficient technology for the production of water based additives, flame retardants dispersions, TiO2 (titanium oxide) & Ca2CO3 (calcium carbonate) dispersion as well as polymer emulsion.

Multimix has introduced new method in the production of pesticide and bio chemicals such as herbicides, insecticides and fungicides in which the powders are being transferred by vacuum process and dispersed with multi stages rotor/stators. As result, production time has been reduced tremendously while achieving fine dispersions.

In the production of any kind of emulsion, Multimix developed the new method of producing emulsion at Nano particle size, which guarantees “No Separation” of the emulsion while at the same time reduces the production time and improves the quality of the emulsion, namely in the production of cream and lotions, mayonnaise, silicone emulsion, margarine, yogurt, cheese, flavor emulsion. Palm oleo related group namely Sime Darby, Mewah and Wilmar are some of the customers currently using Multimix machines.

Multimix has also developed new method of heavy duty mixing with vacuum operation for construction and building materials such as sealants, floorings, adhesives, etc. Multinational company such as BASF, Flowcrete, Elantas (BYK), Mapei are the few customers of CKL Multimix.